VEEYES Engineering Pvt Ltd which is located in 5 mile radius has sophisticated machining facilities & highly skilled technocrats to machine castings manufactured at our 3 steel foundries. Our machine shop Unit I is spread over 20438 sq.meters (220000 sq.ft) area with built-up area about 8175 sq.meters (88000 sq.ft) and Unit II is spread over 2043 sq.meters (22000 sq.ft) area with built-up area about 1393 sq.meters (15000 sq.ft). Today about ONE THIRD of castings produced at our 3 steel foundries are machined at our shop, our goal is to machine ALL of the castings produced by us in the near future.

Our machining equipment includes:

- TREVISAN from Italy – DS450 & DS 600 5 Axis Universal Machining Center

- Mazak from Japan– Horizontal Machining Center

- HWACHEON from Korea CNC Vertical Machining Centre, CNC Vertical Turning Centre, CNC Horizontal Turning Center

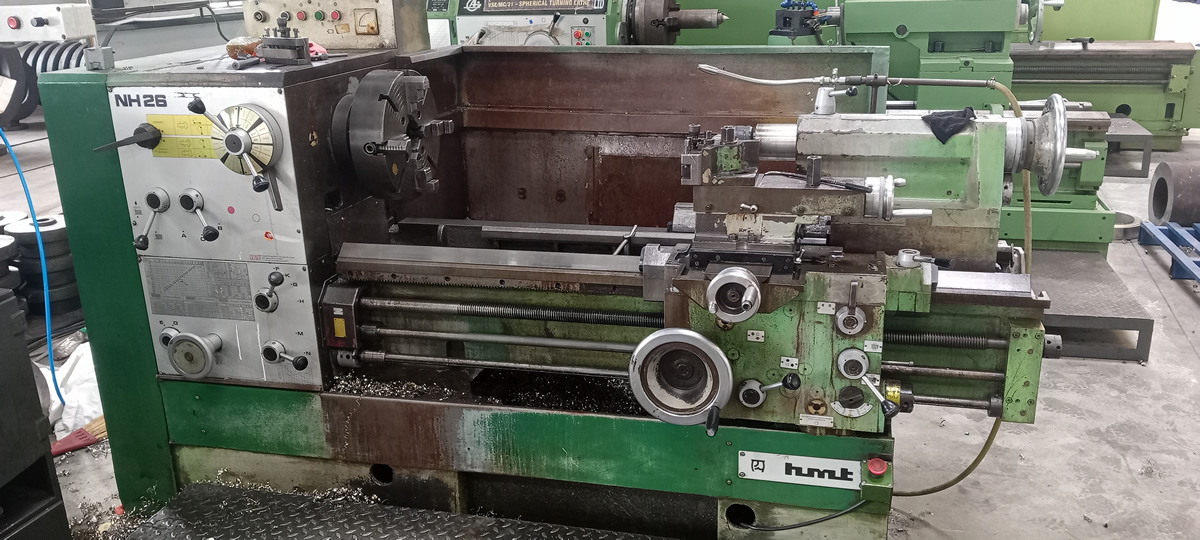

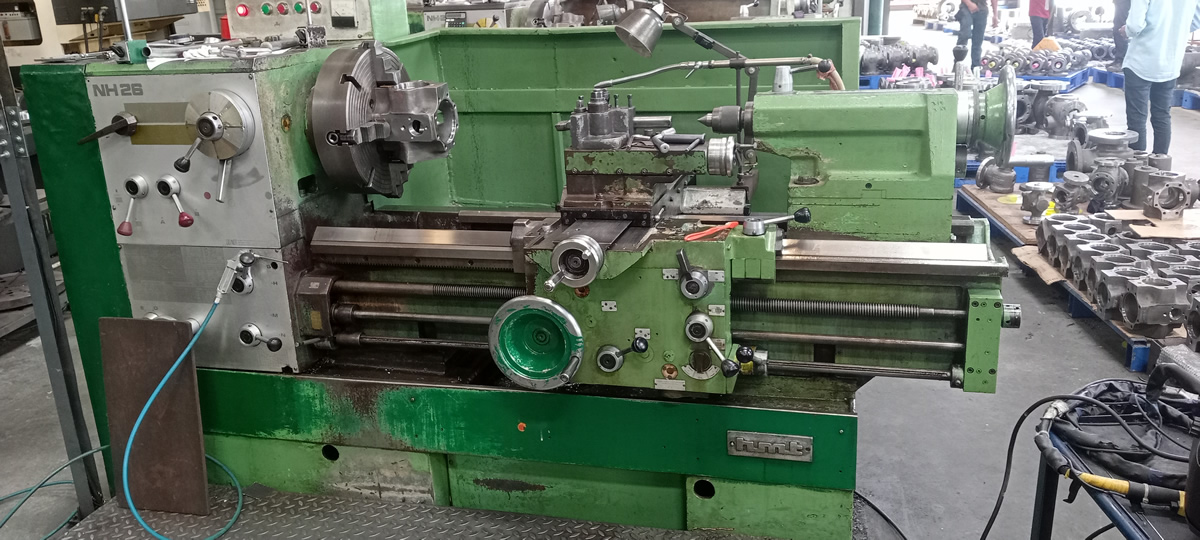

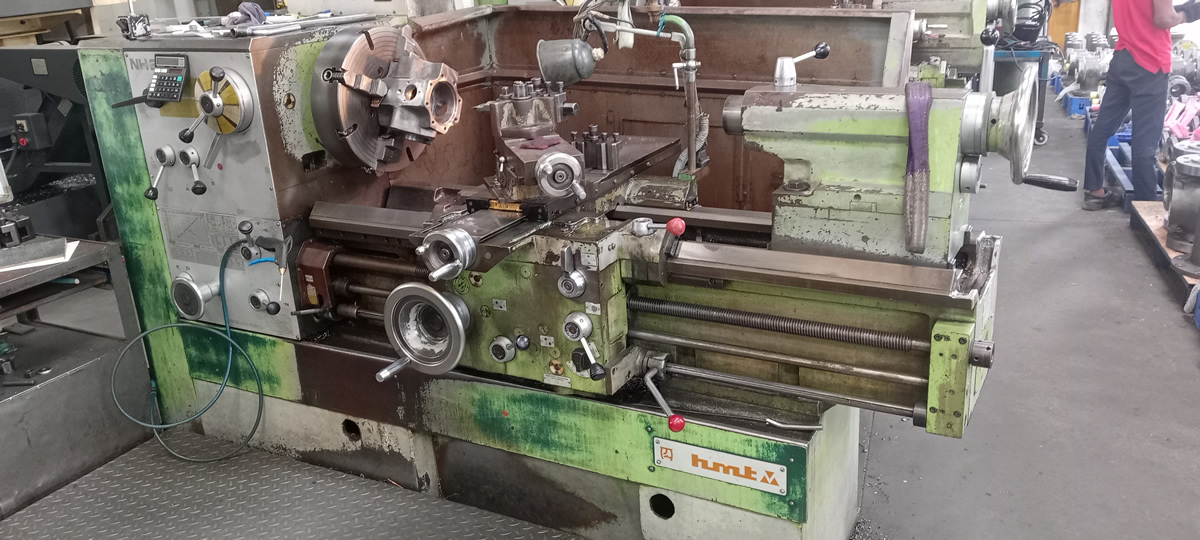

- Conventional HMT Geared Lathes, Turret Lathes, VTL and Horizontal Boring Machine.

Our Machining Capability up to maximum turning diameter 32” size to 2000 mm Dia. The entire production process undergoes dimension and position tolerance test with precise and advanced measuring instruments like CARL ZEISS CNC 3D CMM MODEL – CONTURA G2, 3D Portable CMM – Faro, and 2D Height Master. Our machine shop is equipped with Hydro test for low pressure casting upto 24” size upto 600 Class (1500 PSI) (100 Bar) we do Liquid Penetrate Test, Magnetic Particle Inspection etc to identify leaks and structural flaws on machined castings.

Machine Shop

- Universal Machining Centre

- Horizontal Machining Center

- Vertical Machining Centre

- Horizontal Turning Lathe

- Vertical Turning Lathe

- Ball Grinding Machine

- Spherical Turning Lathe

- Horizontal Boring Machine

- Conventional VTL

- Conventional Lathe

- Cylindrical Grinding

- Radial Drilling Machine

- Hydro Testing

| MACHINE | MAKE | MODEL NO. | SERIAL | CAPACITY / SPEC. |

|---|---|---|---|---|

|

GT Trevisan – Italy | DS450/130C 08-2011 | 1423 |

|

|

GT TREVISAN – Italy | DS 600/ 200C 06-2016 | 2068 |

|

|

GT TREVISAN – Italy | DS 600/ 200CRAM 05-2022 | 2214 |

|

| MACHINE | MAKE | MODEL NO. | SERIAL | CAPACITY / SPEC. |

|---|---|---|---|---|

|

Mazak | Horizontal central nexus 6000 / II 2014-07 | 259432 |

|

|

Mazak | HCN-6800 2018 | 289691 |

|

|

DOOSAN - Korea | NHM 8000 2021-03 | MH0017-000469 |

|

|

BFW | PRIMA 55 PRO | 264 |

|

| MACHINE | MAKE | MODEL NO. | SERIAL | CAPACITY / SPEC. |

|---|---|---|---|---|

|

Hwacheon Machine Tools | SIRIUS - 550 2008.11 | M270356J4NB |

|

|

BFW | BMV60 TC 24 - 2012 | 30031 |

|

|

HWACHEON, Korea | VESTA I 1050B | M243364G4MC |

|

|

DOOSAN - Korea | MYNX 6500/50 | MV0049002396 |

|

|

BFW | X TRON -1577 | 1577-07-2020 |

|

|

DOOSAN - Korea | MYNX 6500/50 II | MV0049-003045 |

|

|

BFW/td> | XTRON-1166/1366 (STD) 2019 | 1166-40 |

|

|

FEELER VMP 580APC | VMP-580 APC 2010 | VKCAP021 |

|

| MACHINE | MAKE | MODEL NO. | SERIAL | CAPACITY / SPEC. |

|---|---|---|---|---|

|

Hwacheon Machine Tools | Hi-Tech 400 2006.10 |

M113354D2WA |

|

|

LMW- Lakshmi Machine Works | TURBO-1000- R20 | 21048/0718/97301 |

|

|

BFW | PL 500 S | H1126 2020 |

|

|

LMW- Lakshmi Machine Works | TURBO-1000- R20 | 05350/0721/116009 |

|

| MACHINE | MAKE | MODEL NO. | SERIAL | CAPACITY / SPEC. |

|---|---|---|---|---|

|

Hwacheon Machine Tools | VT550R | M086354K6GB 2007-04-20 |

|

|

Hwacheon Machine Tools | VT550R | 1036350H4GC |

|

|

DOOSAN - Korea | PUMA V 8300R 2021-02 | MT0049-000681 |

|

|

BFW | BVL 800 - RLCF | VLD/455 2021 |

|

|

Hwacheon Machine Tools | VT550L / VT550R ECO-5VN | M088350D2GB |

|

|

HWACHEON, Korea | VT650R | M095364H4GA |

|

|

DOOSAN - Korea | PUMA V550 2016-08 | MT0013-001587 |

|

|

HONOR | VL-125cm 2017-12 | 80959 |

|

|

TOSHIBA | TUE-150 (S) JULY-2019 | 182491 |

|

|

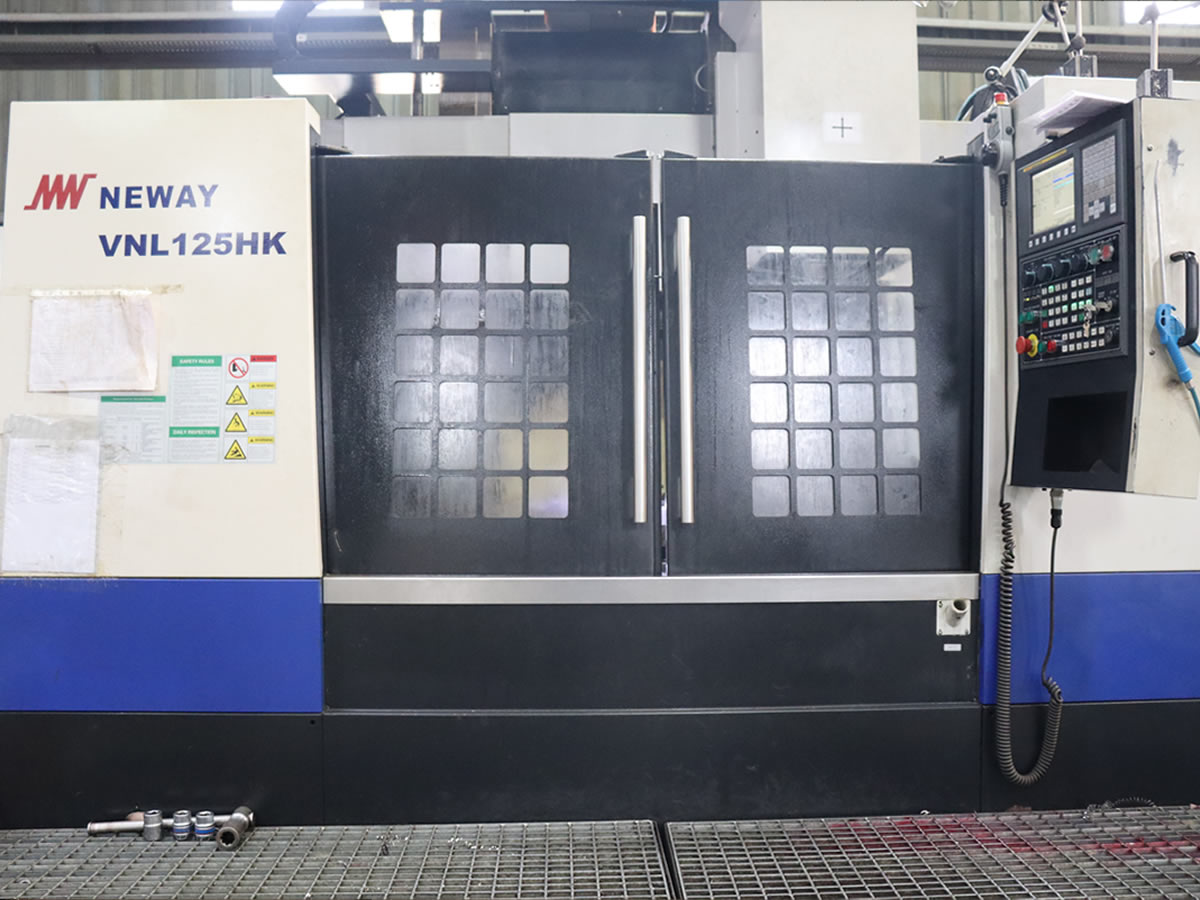

NEWAY | VNL-125-HK | 35382-010-01 |

|

|

NEWAY | VNL250T | 38620-010-01 |

|

| MACHINE | MAKE | MODEL NO. | SERIAL | CAPACITY / SPEC. |

|---|---|---|---|---|

|

MUYEA | QM 580 | -- |

|

|

NEWAY | SMG63HA | 37297-010-01 |

|

|

NEWAY | SMG100H | 37804-010-01 |

|

|

MUYEA | QM100 | 14020 |

|

| MACHINE | MAKE | MODEL NO. | SERIAL | CAPACITY / SPEC. |

|---|---|---|---|---|

|

Byanyang Xinsheng Machine Tools.co.ltd | C6555 | 56 |

|

|

Byanyang Xinsheng Machine Tools.co.ltd | C6595 | 35 |

|

|

ANYANG XINSHENG MACHINE TOOL CO LTD | C65160 | 123 |

|

| MACHINE | MAKE | MODEL NO. | SERIAL | CAPACITY / SPEC. |

|---|---|---|---|---|

|

UNION | -- | -- |

|

| MACHINE | MAKE | MODEL NO. | SERIAL | CAPACITY / SPEC. |

|---|---|---|---|---|

|

I.M.Roman | - | - |

|

|

I.M.Roman | - | - |

|

| MACHINE | MAKE | MODEL NO. | SERIAL | CAPACITY / SPEC. |

|---|---|---|---|---|

|

HMT Machine Tools Ltd | NH-26 | 7307 |

|

|

HMT Machine Tools Ltd | NH-26 | 7313 |

|

|

HMT Machine Tools Ltd | NH-32 | 7324 |

|

|

HMT Machine Tools Ltd | NH-32 | 7320 |

|

|

HMT Machine Tools Ltd | NH-26 | -- |

|

|

HMT Machine Tools Ltd | NH-26 | -- |

|

|

HMT L45 | L45 | -- |

|

| MACHINE | MAKE | MODEL NO. | SERIAL | CAPACITY / SPEC. |

|---|---|---|---|---|

|

HMT Machine Tools Ltd | G17/P | 43030 |

|

| MACHINE | MAKE | MODEL NO. | SERIAL | CAPACITY / SPEC. |

|---|---|---|---|---|

|

Batliboi Ltd | BVR-3 | 2317 |

|

|

Batliboi Ltd | BR-615 | 1069 |

|

|

Batliboi ltd, surat (Gujarat),INDIA | BR 615 | 1069 |

|

|

Batliboi Ltd | BVR-5 | 271307 |

|

| MACHINE | MAKE | MODEL NO. | SERIAL | CAPACITY / SPEC. |

|---|---|---|---|---|

|

SERVO Hydraulics Pvt Ltd | CRONOS JAN/2014 | 80831 |

|

|

Universal Engineering | PTR - 12 | -- |

|

|

TESLEAD | -- | -- |

|

|

TESLEAD | -- | -- |

|

|

TESLEAD | 2022 | -- |

|

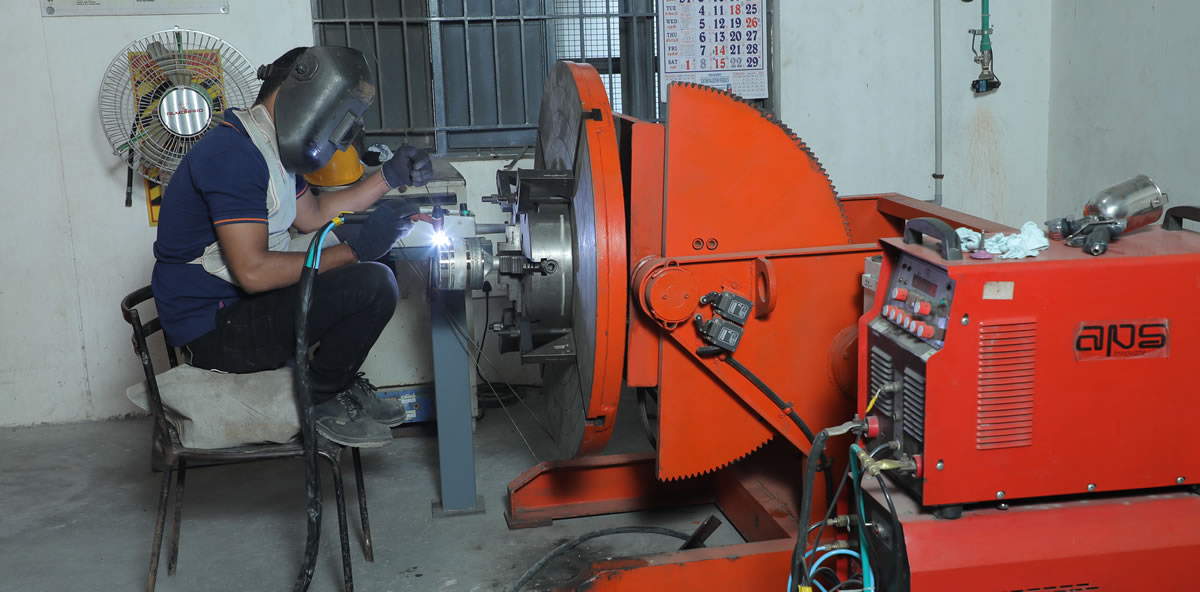

WELDING

Facilities for welding include pre heat arrangements besides air arc gouging. Our welders are qualified as per the requirements of various codes like IBR / ASME/ EN Standards under third parties.

MIG Welding

Plasma Arc Welding